- MOQ 500 kg

- MaterialRss 4,Rss 5

- Hardness40-55 Shore A

- ColorBrowm

- Thickness3-6mm,6-9mm

- TypeRubber & Rubber Products

- ConditionNew

- Country of OriginIndia

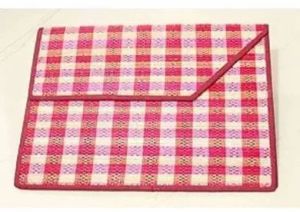

*Rubber Sheets RSS 4 and RSS 5: An Overview** Ribbed Smoked Sheets (RSS) are a cornerstone of natural rubber production, valued for their versatility and cost-effectiveness across industries. Derived from coagulated latex, these sheets undergo smoking for preservation, resulting in distinct grades categorized by quality. RSS 4 and RSS 5 represent mid-to-lower tiers, balancing affordability with functional performance for diverse applications. Below is a detailed breakdown of their properties, uses, and benefits. **RSS 4 Rubber Sheet** *Overview* RSS 4 is a mid-grade natural rubber sheet characterized by moderate impurities and a darker hue due to extended smoking. While it lacks the purity of higher grades (RSS 1-3), it offers a practical balance of mechanical properties and cost efficiency. *Key Features* - **Physical Properties**: Slight inconsistencies in texture and color, with occasional bark or dirt particles. Retains adequate tensile strength (≈20-25 MPa) and elasticity for semi-demanding applications. - **Processing**: Requires standard vulcanization techniques, though impurities may necessitate additional filtration or mixing. Compatible with most manufacturing processes, including extrusion and molding. - **Compliance**: Meets ISO 2000 and ASTM D2227 standards, ensuring reliability for industrial use. *Applications* RSS 4 is ideal for products where performance and cost must align: - **Automotive**: Non-critical tire components (e.g., sidewalls), bushings, and hoses. - **Industrial**: Conveyor belts, gaskets, and vibration dampeners. - **Consumer Goods**: Footwear soles and low-pressure seals. *Benefits* - **Cost-Effective**: Reduces production costs compared to premium grades. - **Durability**: Sufficient resilience for medium-stress environments. - **Versatility**: Adaptable to diverse manufacturing needs. **RSS 5 Rubber Sheet** *Overview* As the lowest RSS grade, RSS 5 prioritizes affordability over performance, featuring higher impurity levels and uneven texture. Its economic value makes it suitable for applications where minimal structural demand exists. *Key Features* - **Physical Properties**: Noticeable imperfections, darker coloration, and variable thickness. Lower tensile strength (≈15-20 MPa) limits use in high-stress scenarios. - **Processing**: May require pre-processing to remove debris; best suited for simple molding or compression methods. *Applications* RSS 5 excels in non-technical, low-cost products: - **Construction**: Rubberized asphalt additives, anti-slip mats. - **Household Items**: Erasers, cheap flooring, and padding. - **Adhesives**: Base material for low-strength bonding solutions. *Benefits* - **Budget-Friendly**: The most economical RSS grade, ideal for cost-sensitive projects. - **Adequate Performance**: Meets basic functional requirements without premium pricing. - **Eco-Conscious**: Natural rubber biodegradability supports sustainable manufacturing. **Comparison and Conclusion** While RSS 4 offers a middle ground for moderate-performance needs, RSS 5 caters to applications where cost trumps precision. The choice hinges on balancing quality requirements with budget constraints. Both grades underscore natural rubber’s adaptability, providing industries with scalable solutions that align with operational and environmental goals. Whether for automotive components or household goods, RSS 4 and RSS 5 remain indispensable in global manufacturing landscapes.